FE models are designed with increased safety “Ex e” for use in areas with potential hazard by dust (zone 21 and 22) or gas (Zone 1) in accordance with directive 94/9/EC and 2014/34/EU.

Vibrator motors with approval according to equipment group II 2.

EC type-examination: KEMA 03 ATEX 2233X, IECEx KEM10.0076X

Temperature class: T3 or T4

Type FE 50 Hz

| TYPE | Temp.

class

|

RPM [min-1] | Output

power [kW]

|

Nominal current

[I]

|

Power factor

[COS ∅]

|

Efficiency |

Ia/In

|

tE [s] |

| FE 40-4-1.2 | T4 | 1405 | 0,25 | 0,7 | 0,8 | 1 | 4 | 23 |

| FE 75-4-2.2 | T4 | 1425 | 0,45 | 1,13 | 0,8 | 1 | 5 | 17 |

| FE 150-4-2.1 | T4 | 1440 | 0,7 | 1,57 | 0,8 | 1 | 7 | 16 |

| FE 190-4-2.3 | T4 | 1440 | 0,7 | 1,57 | 0,8 | 1 | 7 | 16 |

| FE 300-4-4.0 | T4 | 1450 | 1,7 | 3,32 | 0,9 | 1 | 7 | 10 |

| FE…-4-4.3 | T4 | 1450 | 1,7 | 3,32 | 0,9 | 1 | 7 | 10 |

| FE 340-4-4.1 | T3 | 1450 | 2,5 | 4,97 | 0,9 | 1 | 8 | 16 |

| FE 415-4-4.2 | T3 | 1450 | 2,5 | 4,97 | 0,9 | 1 | 8 | 16 |

| TYPE | class class | RPM [min-1] | Output power [kW] | Nominal current [I] | Power factor [COS ∅] |

Efficiency |

Ia/In | tE [s] |

| FE …-6-1.2 | T4 | 935 | 0,2 | 0,8 | 1 | 1 | 3,6 | 24 |

| FE…-6-2.2 | T4 | 940 | 0,3 | 1 | 1 | 1 | 4,2 | 26 |

| FE…-6-2.1 | T4 | 955 | 0,6 | 1,7 | 1 | 1 | 5,4 | 12 |

| FE…-6-2.3 | T4 | 955 | 0,6 | 1,7 | 1 | 1 | 5,3 | 12 |

| FE…-6-3.1 | T4 | 950 | 1,1 | 2,6 | 1 | 1 | 5,3 | 18 |

| FE…-6-3.4 | T4 | 950 | 1,1 | 2,6 | 1 | 1 | 5,3 | 18 |

| FE…-6-4.0 | T4 | 960 | 1,8 | 4,3 | 1 | 1 | 5,8 | 7 |

| FE…-6-4.3 | T4 | 960 | 1,8 | 4,3 | 1 | 1 | 5,8 | 7 |

| FE…-6-4.1 | T4 | 960 | 2,2 | 4,7 | 1 | 1 | 6,6 | 7 |

| FE…-6-4.2 | T4 | 960 | 2,2 | 4,7 | 1 | 1 | 6,6 | 7 |

| FE…-6-7.0 | T4 | 970 | 3 | 6,1 | 1 | 1 | 7,5 | 7 |

| FE…-6-7.1 | T4 | 970 | 3 | 6,1 | 1 | 1 | 7,5 | 7 |

| TYPE | class | RPM [min-1] | Output power [kW] | Nominal current [I] | Power factor [COS ∅] |

Efficiency |

Ia/In | tE [s] |

| FE…-8-4.0 | T3 | 728 | 1,2 | 5 | 1 | 0,8 | 5,3 | 23 |

| FE…-8-7.0 | T4 | 726 | 2,3 | 6 | 1 | 0,8 | 5,6 | 14 |

| FE…-8-7.1 | T4 | 726 | 2,3 | 6 | 1 | 0,8 | 5,6 | 14 |

General specifications

Power Supply:

Voltages from 115 V to 690 V at 50 Hz available

Degree of protection:

IP 66

Thermal class:

F (155 °C) according to DIN EN 60034-1

Tropical insulation:

Standard

Thermal overload protection:

As standard PTC 120 °C

Electrical Connection:

Used exclusively on Ex e motors. These rubber hose assemblies are ideal for heavy mechanical stress according to VDE0282 Part 4, such as the type H07RN-F or A07RN-F or higher grade cable. There are 7-wire cable for zones 21 and 22 used as the PTC and can also be connected with this cable. Specifically: 3x phase, 1x Grounding, 2x PTC, 1x unoccupied. Some motors may also be a 4-wire cable for the live conductors and cables for the PTC, which a second cable gland is used. For this purpose, please contact FRIEDRICH Schwingtechnik.

Mounted on the motor terminal box is an ATEX-sealing plug and ATEX Cable gland. Use only certified components for assembly of the cable. The O-ring for sealing must be installed and undamaged.

Permissible Ambient Temperature:

-20 °C to +40 °C

Operating Mode:

Continuous operation (S1) and discontinuous operation at 100 % centrifugal force.

Hoods:

Hoods made from pressed sheet metal or stainless steel comprise the special shape. A silicone seal provides optimum protection against the ingress of dust and water.

Stock:

The built-in special cylindrical roller bearings with increased load capacity and clearance, are lubricated with a special grease for life.

Assembly:

Without limitation, motors can be mounted in any position.

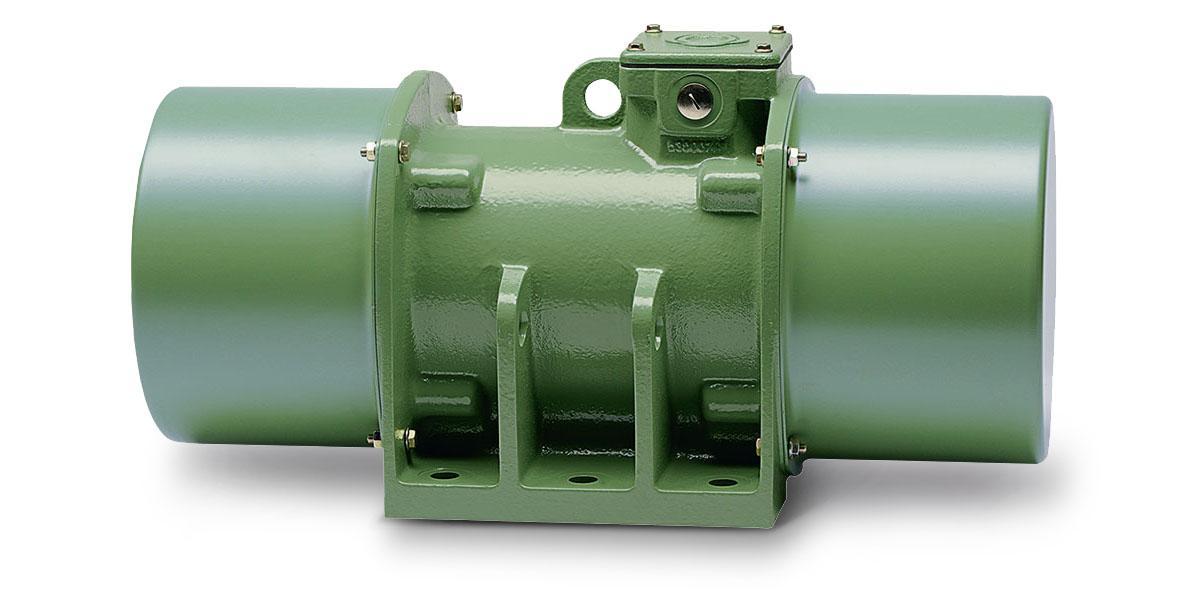

Color Coating:

Standard RAL 6011. Other colors available on request.

Type Code:

The type code is read as follows:

- First block number = Working Moment in kgcm,

(working moment = 2 x static moment) - This is followed by a hyphen and then the pole number,

- Where: 4 = 1460 rpm 6 = 980 rpm (at 50 Hz mains frequency),

- Behind the second dash, the size is specified.