Coupled motors are designed with a one-sided elongated shaft connected by a split end cover with center hole. Two motors are connected by a coupling. This compact design is facilitated by the interaction of four vibration motors and achieves linear vibrating with very high Working Moments.

FK Type 50 Hz

6 pole vibrator motors (980 min-1)

|

TYPE

|

Working- moment [kg cm]

|

Centrifugal force [N]

|

Power consumption [kW]

|

Nominal current at 400 V [A]

|

Power factor [COS ∅]

|

Starting current ratio [IA/IN]

|

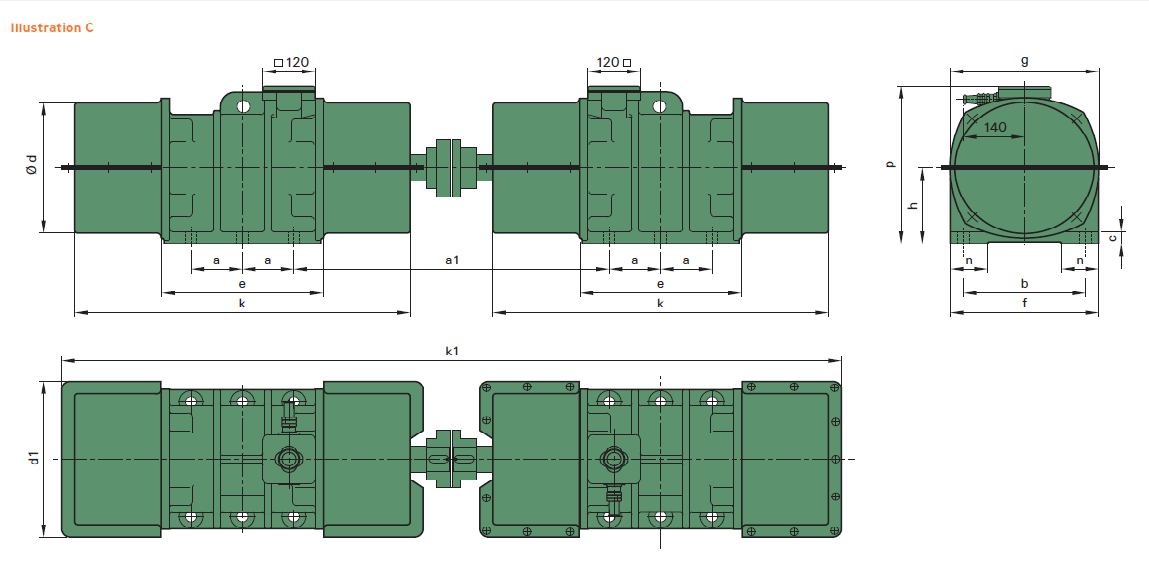

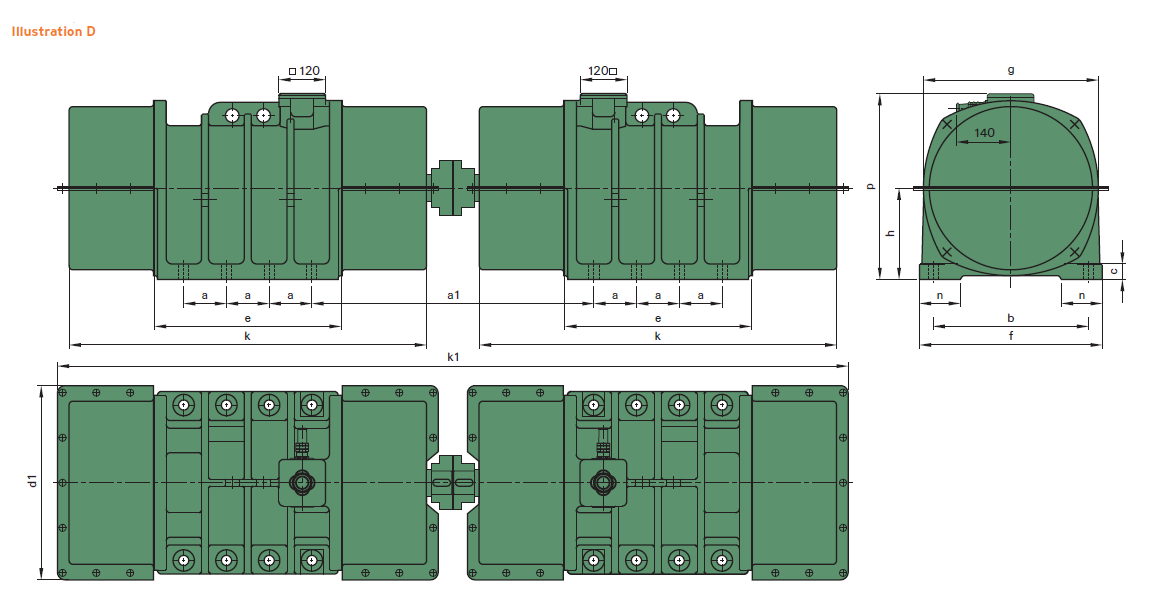

Abbildung Illustration

|

Motor base |

Maße Dimensions Cotesmm |

Weight [kg]

|

Cable [mm]

|

Screw 8.8

|

|||||||||||||

| a | a1 | b | c | d | d1 | e | f | g | h | k | k1 | n | p | ||||||||||||

| FK 1000-6-7.0 | 1000 | 52600 | 4 | 8,27 | 0,84 | 7,5 | C | 6 | 118 | 724 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 770 | 1790 | 90 | 390 | 271 | 4×1,5 | 6xM24 |

| FK 1150-6-7.0 | 1150 | 61000 | 4 | 8,27 | 0,84 | 7,5 | C | 6 | 118 | 864 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 910 | 2070 | 90 | 390 | 281 | 4×1,5 | 6xM24 |

| FK 1300-6-7.0 | 1300 | 68400 | 4 | 8,27 | 0,84 | 7,5 | C | 6 | 118 | 864 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 910 | 2070 | 90 | 390 | 285 | 4×1,5 | 6xM24 |

| FK 1400-6-7.0 | 1400 | 73700 | 4 | 8,27 | 0,84 | 7,5 | C | 6 | 118 | 864 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 910 | 2070 | 90 | 390 | 296 | 4×1,5 | 6xM24 |

| FK 1600-6-7.0 | 1600 | 84300 | 4 | 8,27 | 0,84 | 7,5 | C | 6 | 118 | 904 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 950 | 2150 | 90 | 390 | 310 | 4×1,5 | 6xM24 |

| FK 1750-6-7.8 | 1750 | 92100 | 5,6 | 12,3 | 0,66 | 7,3 | C | 6 | 118 | 830 | 280 | 35 | 360 | 440 | 370 | 340 | 400 | 210 | 870 | 1996 | 85 | 425 | 388 | 4×2,5 | 6xM24 |

| FK 2000-6-7.8 | 2000 | 105300 | 5,6 | 12,3 | 0,66 | 7,3 | C | 6 | 118 | 890 | 280 | 35 | 360 | 440 | 370 | 340 | 400 | 210 | 930 | 2116 | 85 | 425 | 397 | 4×2,5 | 6xM24 |

| FK 1750-6-8.0 | 1750 | 92100 | 7,5 | 14,25 | 0,68 | 7,6 | D | 8 | 110 | 776 | 350 | 35 | 360 | 440 | 470 | 420 | 400 | 210 | 970 | 2136 | 90 | 430 | 450 | 4×2,5 | 8xM24 |

| FK 2000-6-8.0 | 2000 | 105300 | 7,5 | 14,25 | 0,68 | 7,6 | D | 8 | 110 | 836 | 350 | 35 | 360 | 440 | 470 | 420 | 400 | 210 | 1030 | 2256 | 90 | 430 | 470 | 4×2,5 | 8xM24 |

| FK 2500-6-8.9 | 2500 | 132500 | 7,5 | 14,25 | 0,68 | 7,6 | D | 8.9 | 110 | 730 | 350 | 35 | 420 | 500 | 470 | 440 | 450 | 235 | 910 | 2030 | 100 | 460 | 510 | 4×2,5 | 8xM30 |

| FK 3000-6-8.9 | 3000 | 158000 | 7,5 | 14,25 | 0,58 | 7,6 | D | 8.9 | 110 | 840 | 350 | 35 | 420 | 500 | 470 | 440 | 450 | 235 | 1020 | 2250 | 100 | 460 | 536 | 4×2,5 | 8xM30 |

| FK 2500-6-9.0 | 2500 | 132500 | 8 | 18,34 | 0,7 | 9,5 | D | 9 | 110 | 726 | 400 | 45 | 420 | 500 | 480 | 470 | 450 | 235 | 920 | 2036 | 105 | 480 | 540 | 4×2,5 | 8xM24 |

| FK 3200-6-9.0 | 3200 | 170000 | 8 | 18,34 | 0,7 | 9,5 | D | 9 | 110 | 836 | 400 | 45 | 420 | 500 | 480 | 470 | 450 | 235 | 1030 | 2256 | 105 | 480 | 580 | 4×2,5 | 8xM24 |

|

TYPE

|

Working- moment [kg cm]

|

Centrifugal force [N]

|

Power consumption [kW]

|

Nominal current at 400 V [A]

|

Power factor [COS ∅]

|

Starting current ratio [IA/IN]

|

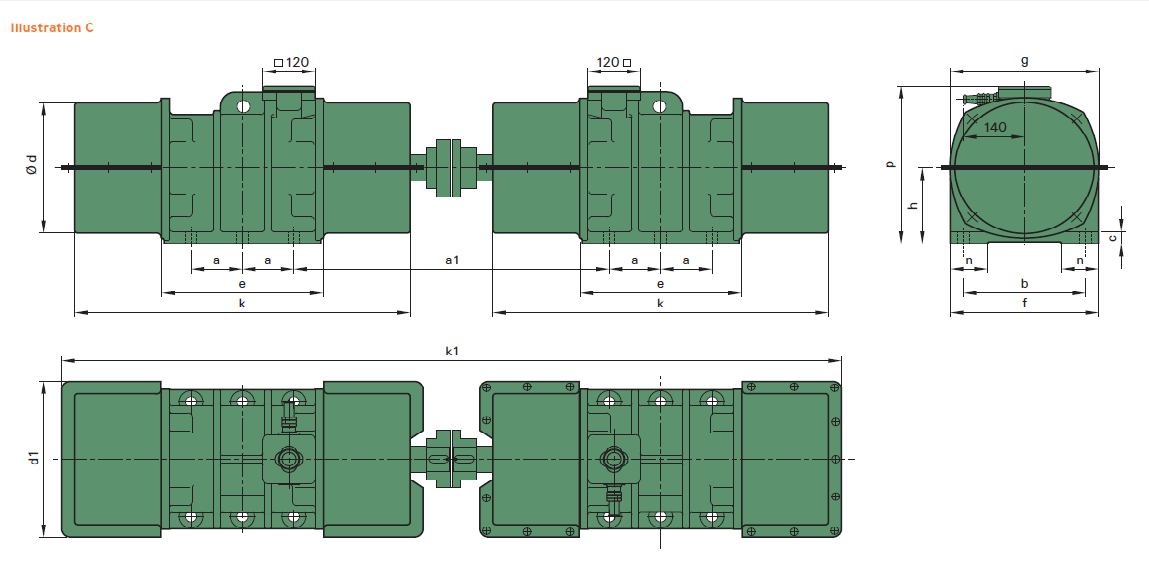

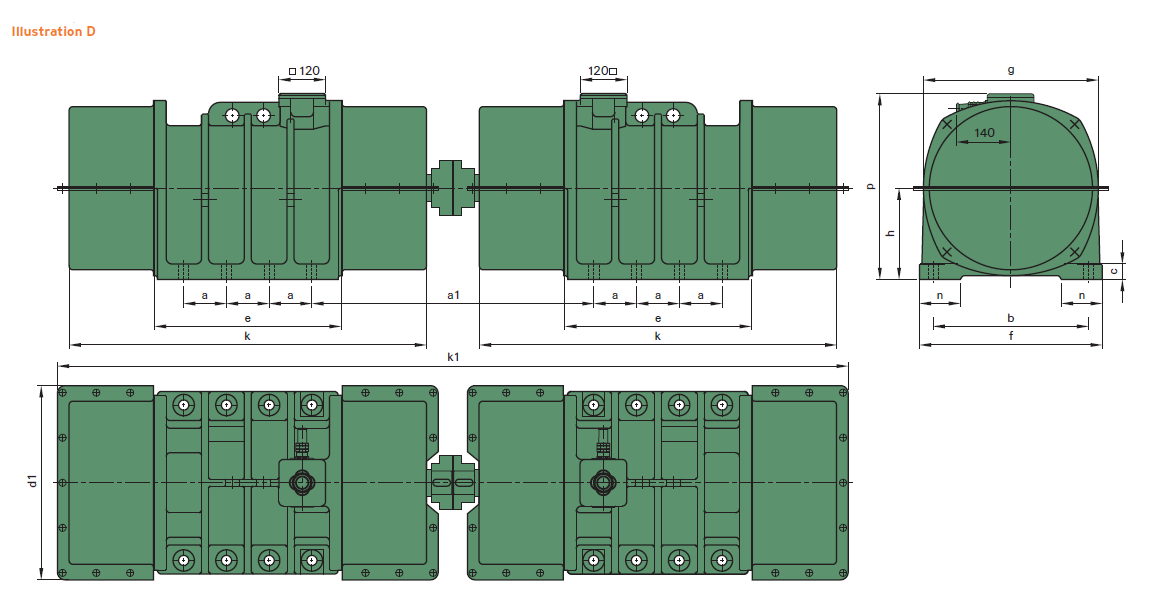

Abbildung Illustration

|

Motor base |

Maße Dimensions Cotesmm |

Weight [kg]

|

Cable [mm]

|

Screw 8.8

|

|||||||||||||

| a | a1 | b | c | d | d1 | e | f | g | h | k | k1 | n | p | ||||||||||||

| FK 1400-8-7.0 | 1400 | 42000 | 3 | 7,41 | 0,66 | 6 | C | 6 | 118 | 864 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 910 | 2070 | 90 | 390 | 296 | 4×1,5 | 6xM24 |

| FK 1600-8-7.0 | 1600 | 48000 | 3 | 7,41 | 0,66 | 6 | C | 6 | 118 | 904 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 950 | 2150 | 90 | 390 | 310 | 4×1,5 | 6xM24 |

| FK 1750-8-7.8 | 1750 | 52500 | 4 | 9,87 | 0,68 | 6,4 | C | 6 | 118 | 830 | 280 | 35 | 360 | 440 | 370 | 340 | 400 | 210 | 870 | 1996 | 85 | 425 | 388 | 4×2,5 | 6xM24 |

| FK 2000-8-7.8 | 2000 | 60000 | 4 | 9,87 | 0,68 | 6,4 | C | 6 | 118 | 890 | 280 | 35 | 360 | 440 | 370 | 340 | 400 | 210 | 930 | 2116 | 85 | 425 | 397 | 4×2,5 | 6xM24 |

| FK 2200-8-8.0 | 2200 | 66000 | 4,5 | 10,83 | 0,7 | 6,1 | D | 8 | 110 | 836 | 350 | 35 | 360 | 440 | 470 | 420 | 400 | 210 | 1030 | 2256 | 90 | 430 | 490 | 4×2,5 | 8xM24 |

| FK 2500-8-8.9 | 2500 | 75000 | 4,5 | 10,83 | 0,7 | 6,1 | D | 8.9 | 110 | 730 | 350 | 35 | 420 | 500 | 470 | 440 | 450 | 235 | 910 | 2030 | 100 | 460 | 510 | 4×2,5 | 8xM30 |

| FK 3000-8-8.9 | 3000 | 90100 | 4,5 | 10,83 | 0,7 | 6,1 | D | 8.9 | 110 | 840 | 350 | 35 | 420 | 500 | 470 | 440 | 450 | 235 | 1020 | 2250 | 100 | 460 | 536 | 4×2,5 | 8xM30 |

| FK 2500-8-9.0 | 2500 | 75000 | 7 | 18,15 | 0,56 | 7,3 | D | 9 | 110 | 726 | 400 | 45 | 420 | 500 | 480 | 470 | 450 | 235 | 920 | 2036 | 105 | 480 | 540 | 4×2,5 | 8xM24 |

| FK 3200-8-9.0 | 3200 | 96000 | 7 | 18,15 | 0,56 | 7,3 | D | 9 | 110 | 836 | 400 | 45 | 420 | 500 | 480 | 470 | 450 | 235 | 1030 | 2256 | 105 | 480 | 580 | 4×2,5 | 8xM24 |

| FK 4000-8-9.0 | 4000 | 120000 | 7 | 18,15 | 0,56 | 7,3 | D | 9 | 110 | 936 | 400 | 45 | 420 | 500 | 480 | 470 | 450 | 235 | 1130 | 2456 | 105 | 480 | 600 | 4×2,5 | 8xM24 |

General specifications

Power Supply:

Voltages from 115 V to 690 V at 50 Hz and 60 Hz available

Degree of Protection:

IP 54

Thermal class:

F (155 °C) according to DIN EN 60034-1

Tropical Insulation:

Standard

Electrical Connection:

Use high flexible cable for heavy mechanical stress for example: H07RN-F or A07RN-F according to DIN VDE 0282.

Permissible ambient temperature:

-20 to +40 °C

Operating mode:

Continuous operation (S1) and discontinuous operation at 100 % centrifugal force.

Hoods:

Hoods made from pressed sheet metal, comprise the special shape. A silicone seal provides optimum protection against the ingress of dust and water.

Assembly:

Without limitation, motors can be mounted in any position.

Color Coating:

Standard RAL 6011. Other colors available on request.

Type code:

The type code is read as follows:

- First block number = working moment in kgcm,

(working moment = 2 x static Moment) - This is followed by a hyphen and then the pole number,

- Where: 4 = 1460 rpm 6 = 980 rpm (at 50 Hz mains frequency),

- Behind the second dash, the size is specified.

Special designs and accessories available on request:

- Anti-condensation heating,

- Thermistor,

- Split end covers (see special catalog),

- Special steel bearing retainer (see special catalog),

- Waterproof terminal box with a special sealant shed, connection cables with different Cable specifications in different lengths available.