FHG motors are equipped with split hoods made from pressed sheet metal and welded flange. The special shape and an O-ring seal of silicone to the motor and a rubber gasket between the split hoods provide perfect protection against the ingress of dust and water.

Split hoods are available both in powder-coated deep-drawn sheet and stainless steel. The color coating with powder-coated sheet metal deep drawing is standard RAL 6011.

In confined spaces, a split hood is beneficial. The split hood allows easy access and disassembly in order to adjust the weights on the motor.

Motors can be equipped with one or two split hoods. The advantage is greater and design flexible.

FHG Type 50 Hz

2 pole vibrator motors (2860 min-1)

|

TYPE |

Working- moment [kg cm] |

Centrifugal force [N]

|

Power consumption [kW] |

Nominal current at 400 V [A] |

Power factor [COS ∅] |

Starting current ratio [IA/IN] |

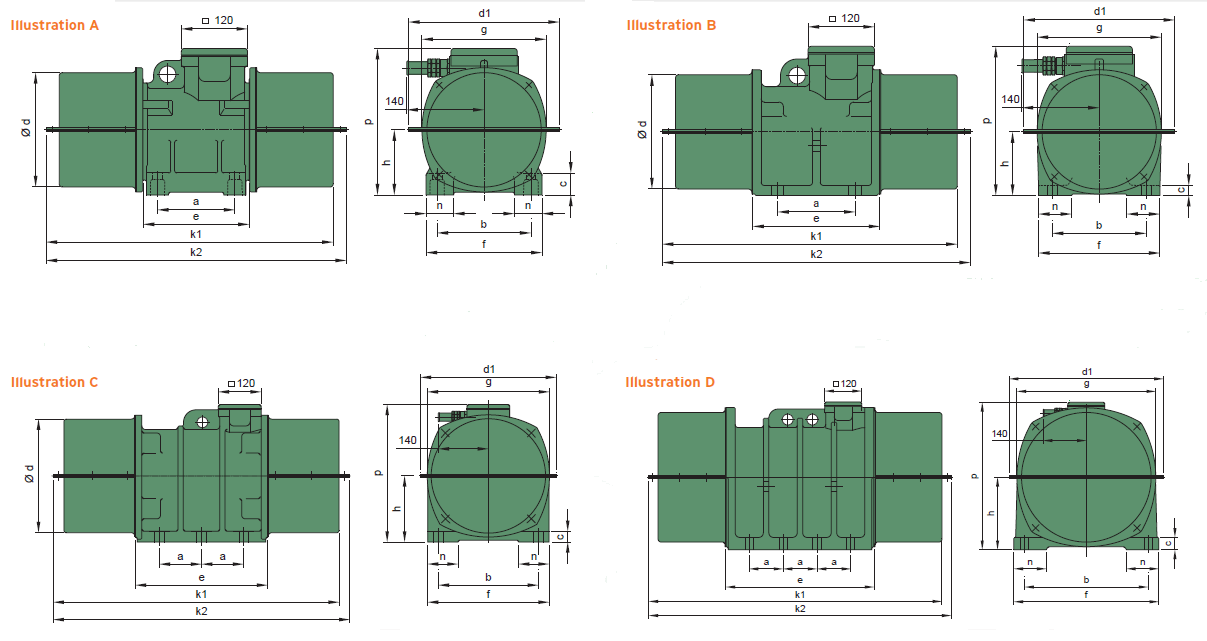

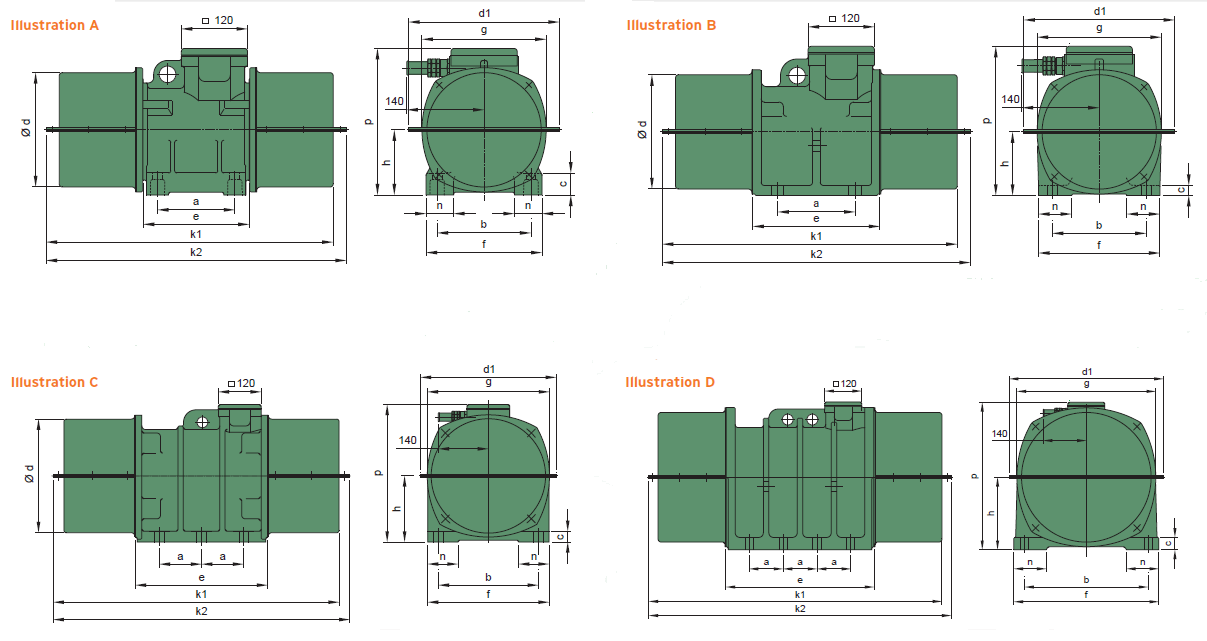

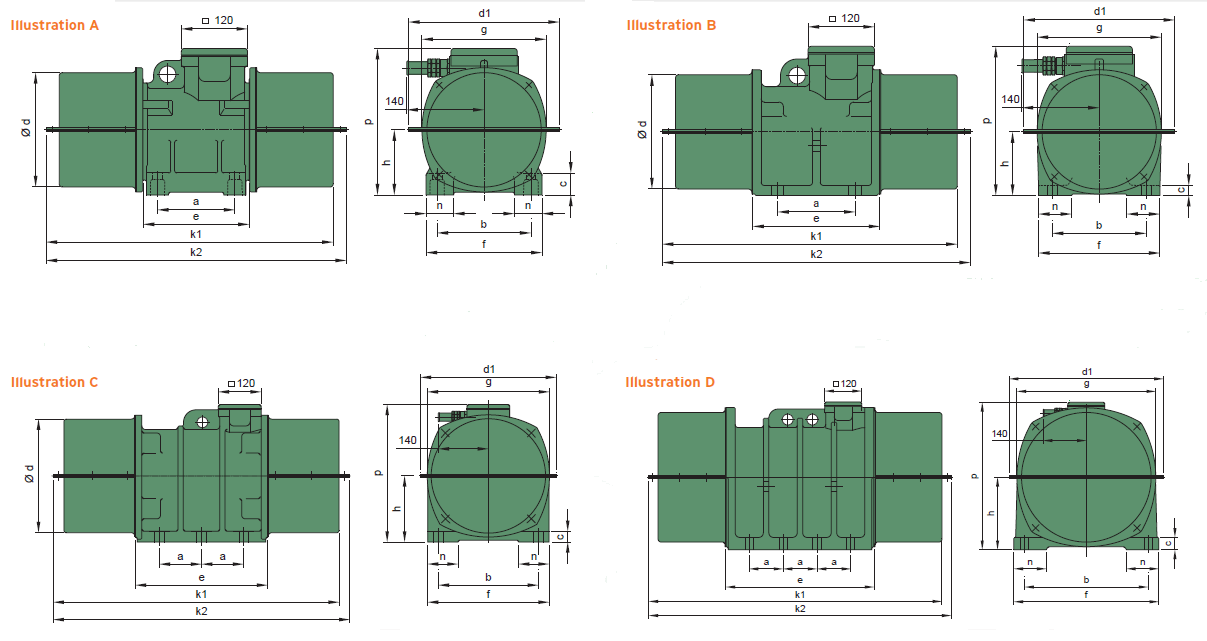

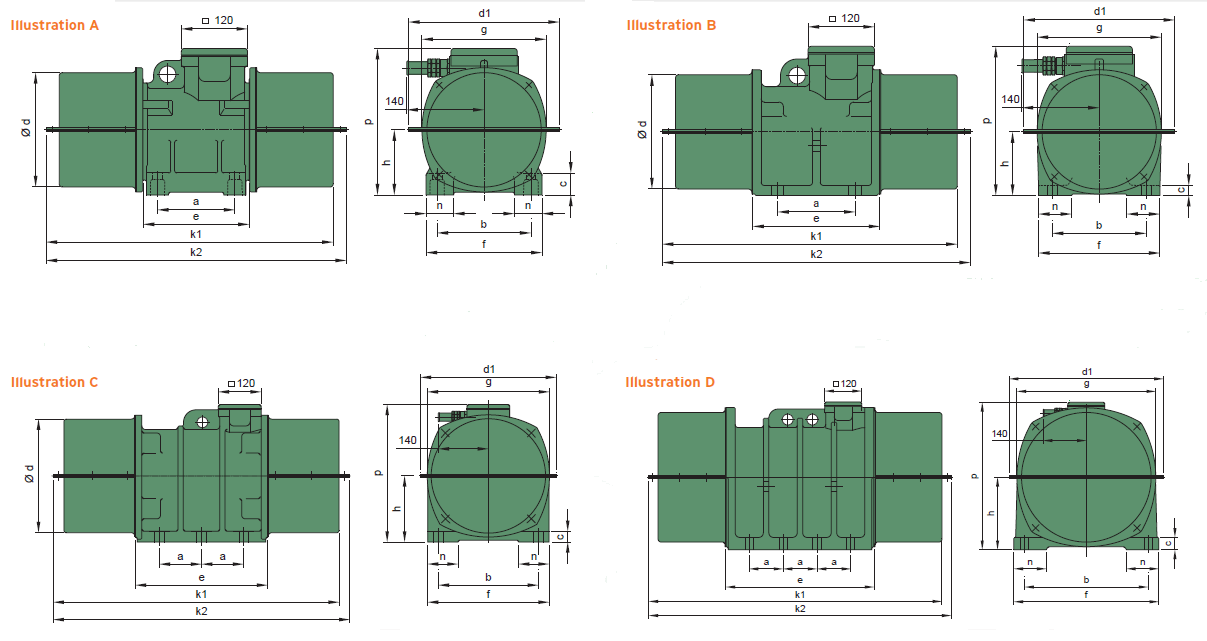

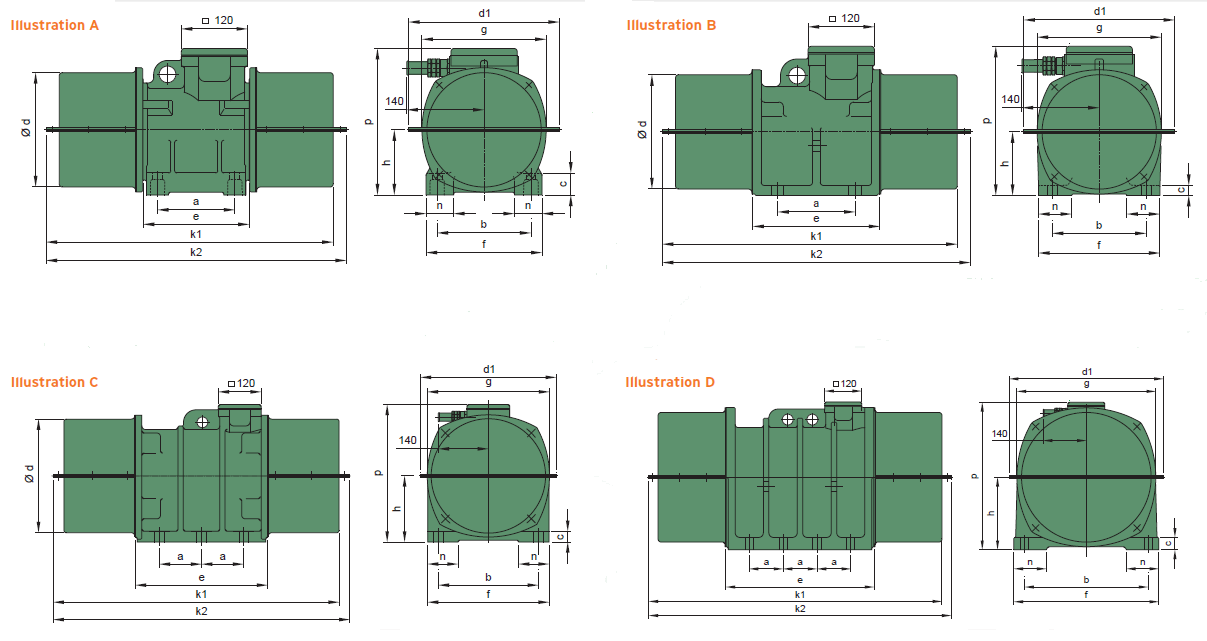

Abbildung Illustration |

Motor base |

Maße Dimensions Cotesmm |

Weight [kg] |

Cable [mm] |

Screw 8.8 |

||||||||||||

| a | b | c | d | d1 | e | f | g | h | k1 | k2 | n | p | ||||||||||||

| FHG 23-2-2.2 | 23 | 10320 | 0,75 | 1,75 | 0,82 | 7,7 | A | 2 | 140 | 170 | 40 | 207 | 255 | 192 | 210 | 225 | 118 | 454 | 478 | 50 | 268 | 42 | 4×1,5 | 4xM16 |

| FHG 32-2-2.1 | 32 | 14400 | 1,2 | 2,28 | 0,85 | 7,8 | B | 2 | 140 | 170 | 20 | 207 | 255 | 230 | 220 | 225 | 115 | 468 | 492 | 60 | 274 | 67 | 4×1,5 | 4xM16 |

| FHG 42-2-2.1 | 42 | 18900 | 1,2 | 2,28 | 0,85 | 7,8 | B | 2 | 140 | 170 | 20 | 207 | 255 | 230 | 220 | 225 | 115 | 468 | 492 | 60 | 274 | 69 | 4×1,5 | 4xM16 |

|

TYPE |

Working- moment [kg cm] |

Centrifugal force [N]

|

Power consumption [kW] |

Nominal current at 400 V [A] |

Power factor [COS ∅] |

Starting current ratio [IA/IN] |

Abbildung Illustration |

Motor base |

Maße Dimensions Cotesmm |

Weight [kg] |

Cable [mm] |

Screw 8.8 |

||||||||||||

| a | b | c | d | d1 | e | f | g | h | k1 | k2 | n | p | ||||||||||||

| FHG 75-4-2.2 | 75 | 8800 | 0,6 | 1,43 | 0,8 | 5,7 | A | 2 | 140 | 170 | 40 | 207 | 255 | 192 | 210 | 225 | 118 | 454 | 478 | 50 | 268 | 46 | 4×1,5 | 4xM16 |

| FHG 95-4-2.2 | 95 | 11100 | 0,6 | 1,43 | 0,8 | 5,7 | A | 2 | 140 | 170 | 40 | 207 | 255 | 192 | 210 | 225 | 118 | 454 | 478 | 50 | 268 | 50 | 4×1,5 | 4xM16 |

| FHG 125-4-2.4 | 125 | 14620 | 0,6 | 1,43 | 0,8 | 5,7 | A | 2 | 140 | 170 | 40 | 207 | 255 | 192 | 210 | 225 | 118 | 520 | 544 | 50 | 268 | 58 | 4×1,5 | 4xM16 |

| FHG 150-4-2.4 | 150 | 17500 | 0,6 | 1,43 | 0,8 | 5,7 | A | 2 | 140 | 170 | 40 | 207 | 255 | 192 | 210 | 225 | 118 | 520 | 544 | 50 | 268 | 60 | 4×1,5 | 4xM16 |

| FHG 150-4-2.1 | 150 | 17500 | 1,1 | 2,33 | 0,82 | 6,6 | B | 2 | 140 | 170 | 20 | 207 | 255 | 230 | 220 | 225 | 115 | 538 | 562 | 60 | 274 | 72 | 4×1,5 | 4xM16 |

| FHG 190-4-2.3 | 190 | 22300 | 1,1 | 2,33 | 0,82 | 6,6 | B | 2 | 140 | 170 | 20 | 250 | 300 | 230 | 220 | 272 | 140 | 545 | 570 | 60 | 300 | 82 | 4×1,5 | 4xM16 |

| FHG 200-4-2.1 | 200 | 23400 | 1,1 | 2,33 | 0,82 | 6,6 | B | 2 | 140 | 170 | 20 | 207 | 255 | 230 | 220 | 225 | 115 | 594 | 618 | 60 | 274 | 75 | 4×1,5 | 4xM16 |

| FHG 235-4-3.4 | 235 | 27500 | 1,4 | 3,04 | 0,87 | 9,1 | C | 3 | 83 | 230 | 25 | 280 | 360 | 260 | 280 | 300 | 160 | 530 | 560 | 75 | 330 | 110 | 4×1,5 | 6xM20 |

| FHG 285-4-3.4 | 285 | 33350 | 1,4 | 3,04 | 0,87 | 9,1 | C | 3 | 83 | 230 | 25 | 280 | 360 | 260 | 280 | 300 | 160 | 530 | 560 | 75 | 330 | 116 | 4×1,5 | 6xM20 |

| FHG 300-4-4.0 | 300 | 35000 | 2 | 3,8 | 0,87 | 6,8 | C | 4 | 105 | 248 | 28 | 280 | 360 | 300 | 310 | 300 | 160 | 570 | 600 | 80 | 344 | 128 | 4×1,5 | 6xM20 |

| FHG 340-4-4.1 | 340 | 39700 | 3 | 5,89 | 0,87 | 7,8 | C | 4 | 105 | 248 | 28 | 280 | 360 | 300 | 310 | 300 | 160 | 570 | 600 | 80 | 344 | 138 | 4×1,5 | 6xM20 |

| FHG 415-4-4.1 | 415 | 48600 | 3 | 5,89 | 0,87 | 7,8 | C | 4 | 105 | 248 | 28 | 280 | 360 | 300 | 310 | 300 | 160 | 640 | 670 | 80 | 344 | 146 | 4×1,5 | 6xM20 |

| FHG 430-4-6.0 | 430 | 50200 | 3,5 | 7,03 | 0,84 | 5,6 | C | 6 | 118 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 710 | 740 | 90 | 390 | 197 | 4×1,5 | 6xM24 |

| FHG 550-4-7.0 | 550 | 64200 | 7 | 15,2 | 0,86 | 7,6 | C | 6 | 118 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 710 | 740 | 90 | 390 | 250 | 4×2,5 | 6xM24 |

| FHG 700-4-7.1 | 700 | 81800 | 7 | 15,2 | 0,86 | 7,6 | C | 6 | 118 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 710 | 740 | 90 | 390 | 275 | 4×2,5 | 6xM24 |

| FHG 800-4-7.1 | 800 | 93600 | 7 | 15,2 | 0,86 | 7,6 | C | 6 | 118 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 800 | 830 | 90 | 390 | 282 | 4×2,5 | 6xM24 |

| FHG 900-4-8.0 | 900 | 105200 | 8 | 17,1 | 0,87 | 7,6 | D | 8 | 110 | 350 | 35 | 360 | 440 | 470 | 420 | 400 | 210 | 1000 | 1030 | 90 | 430 | 377 | 4×2,5 | 8xM24 |

|

TYPE |

Working- moment [kg cm] |

Centrifugal force [N]

|

Power consumption [kW] |

Nominal current at 400 V [A] |

Power factor [COS ∅] |

Starting current ratio [IA/IN] |

Abbildung Illustration |

Motor base |

Maße Dimensions Cotesmm |

Weight [kg] |

Cable [mm] |

Screw 8.8 |

||||||||||||

| a | b | c | d | d1 | e | f | g | h | k1 | k2 | n | p | ||||||||||||

| FHG 95-6-2.2 | 95 | 5000 | 0,5 | 1,52 | 0,7 | 4,2 | A | 2 | 140 | 170 | 40 | 207 | 255 | 192 | 210 | 225 | 118 | 454 | 478 | 50 | 268 | 50 | 4×1,5 | 4xM16 |

| FHG 120-6-2.2 | 120 | 6400 | 0,5 | 1,52 | 0,7 | 4,2 | A | 2 | 140 | 170 | 40 | 207 | 255 | 192 | 210 | 225 | 118 | 454 | 478 | 50 | 268 | 51 | 4×1,5 | 4xM16 |

| FHG 150-6-2.2 | 150 | 7900 | 0,5 | 1,52 | 0,7 | 4,2 | A | 2 | 140 | 170 | 40 | 207 | 255 | 192 | 210 | 225 | 118 | 520 | 544 | 50 | 268 | 53 | 4×1,5 | 4xM16 |

| FHG 175-6-2.4 | 175 | 9300 | 0,5 | 1,52 | 0,7 | 4,2 | A | 2 | 140 | 170 | 40 | 207 | 255 | 192 | 210 | 225 | 118 | 520 | 544 | 50 | 268 | 63 | 4×1,5 | 4xM16 |

| FHG 200-6-2.4 | 200 | 10600 | 0,5 | 1,52 | 0,7 | 4,2 | A | 2 | 140 | 170 | 40 | 207 | 255 | 192 | 210 | 225 | 118 | 580 | 604 | 50 | 268 | 66 | 4×1,5 | 4xM16 |

| FHG 225-6-2.4 | 225 | 11950 | 0,5 | 1,52 | 0,7 | 4,2 | A | 2 | 140 | 170 | 40 | 207 | 255 | 192 | 210 | 225 | 118 | 580 | 604 | 50 | 268 | 69 | 4×1,5 | 4xM16 |

| FHG 200-6-2.1 | 200 | 10600 | 1 | 1,71 | 0,7 | 5,3 | B | 2 | 140 | 170 | 20 | 207 | 255 | 230 | 220 | 225 | 115 | 594 | 618 | 60 | 274 | 77 | 4×1,5 | 4xM16 |

| FHG 250-6-2.3 | 250 | 13200 | 1 | 1,71 | 0,7 | 5,3 | B | 2 | 140 | 170 | 20 | 250 | 300 | 230 | 220 | 272 | 140 | 545 | 570 | 60 | 300 | 88 | 4×1,5 | 4xM16 |

| FHG 300-6-2.3 | 300 | 15800 | 1 | 1,71 | 0,7 | 5,3 | B | 2 | 140 | 170 | 20 | 250 | 300 | 230 | 220 | 272 | 140 | 545 | 570 | 60 | 300 | 92 | 4×1,5 | 4xM16 |

| FHG 340-6-2.3 | 340 | 18000 | 1 | 1,71 | 0,7 | 5,3 | B | 2 | 140 | 170 | 20 | 250 | 300 | 230 | 220 | 272 | 140 | 615 | 640 | 60 | 300 | 98 | 4×1,5 | 4xM16 |

| FHG 400-6-3.1 | 400 | 21000 | 1,7 | 3,23 | 0,77 | 5,3 | C | 3 | 83 | 230 | 25 | 250 | 300 | 260 | 280 | 272 | 150 | 645 | 670 | 75 | 320 | 123 | 4×1,5 | 6xM20 |

| FHG 500-6-3.4 | 500 | 26300 | 1,7 | 3,23 | 0,77 | 5,3 | C | 3 | 83 | 230 | 25 | 280 | 360 | 260 | 280 | 300 | 160 | 600 | 630 | 75 | 330 | 136 | 4×1,5 | 6xM20 |

| FHG 600-6-3.4 | 600 | 31800 | 1,7 | 3,23 | 0,77 | 5,3 | C | 3 | 83 | 230 | 25 | 280 | 360 | 260 | 280 | 300 | 160 | 670 | 700 | 75 | 330 | 147 | 4×1,5 | 6xM20 |

| FHG 680-6-3.4 | 680 | 35800 | 1,7 | 3,23 | 0,77 | 5,3 | C | 3 | 83 | 230 | 25 | 280 | 360 | 260 | 280 | 300 | 160 | 670 | 700 | 75 | 330 | 155 | 4×1,5 | 6xM20 |

| FHG 500-6-4.0 | 500 | 26300 | 2,2 | 5,23 | 0,74 | 5,8 | C | 4 | 105 | 248 | 28 | 280 | 360 | 300 | 310 | 300 | 160 | 640 | 670 | 80 | 344 | 153 | 4×1,5 | 6xM20 |

| FHG 550-6-4.1 | 550 | 29000 | 2,7 | 6,18 | 0,8 | 6,6 | C | 4 | 105 | 248 | 28 | 280 | 360 | 300 | 310 | 300 | 160 | 710 | 740 | 80 | 344 | 159 | 4×1,5 | 6xM20 |

| FHG 680-6-4.1 | 680 | 35800 | 2,7 | 6,18 | 0,8 | 6,6 | C | 4 | 105 | 248 | 28 | 280 | 360 | 300 | 310 | 300 | 160 | 710 | 740 | 80 | 344 | 168 | 4×1,5 | 6xM20 |

| FHG 780-6-4.1 | 780 | 41340 | 2,7 | 6,18 | 0,8 | 6,6 | C | 4 | 105 | 248 | 28 | 280 | 360 | 300 | 310 | 300 | 160 | 830 | 860 | 80 | 344 | 186 | 4×1,5 | 6xM20 |

| FHG 700-6-4.7 | 700 | 36900 | 2,7 | 6,71 | 0,6 | 6,6 | C | 4 | 105 | 248 | 28 | 320 | 400 | 300 | 310 | 342 | 180 | 730 | 760 | 80 | 365 | 187 | 4×1,5 | 6xM20 |

| FHG 850-6-4.7 | 850 | 44800 | 2,7 | 6,71 | 0,6 | 6,6 | C | 4 | 105 | 248 | 28 | 320 | 400 | 300 | 310 | 342 | 180 | 730 | 760 | 80 | 365 | 196 | 4×1,5 | 6xM20 |

| FHG 1000-6-4.7 | 1000 | 52600 | 2,7 | 6,71 | 0,6 | 6,6 | C | 4 | 105 | 248 | 28 | 320 | 400 | 300 | 310 | 342 | 180 | 730 | 760 | 80 | 365 | 204 | 4×1,5 | 6xM20 |

| FHG 1000-6-7.0 | 1000 | 52600 | 4 | 8,27 | 0,84 | 7,5 | C | 6 | 118 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 800 | 830 | 90 | 390 | 271 | 4×1,5 | 6xM24 |

| FHG 1150-6-7.0 | 1150 | 61000 | 4 | 8,27 | 0,84 | 7,5 | C | 6 | 118 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 940 | 970 | 90 | 390 | 281 | 4×1,5 | 6xM24 |

| FHG 1300-6-7.0 | 1300 | 68400 | 4 | 8,27 | 0,84 | 7,5 | C | 6 | 118 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 940 | 970 | 90 | 390 | 285 | 4×1,5 | 6xM24 |

| FHG 1400-6-7.0 | 1400 | 73700 | 4 | 8,27 | 0,84 | 7,5 | C | 6 | 118 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 940 | 970 | 90 | 390 | 296 | 4×1,5 | 6xM24 |

| FHG 1600-6-7.0 | 1600 | 84300 | 4 | 8,27 | 0,84 | 7,5 | C | 6 | 118 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 980 | 1010 | 90 | 390 | 310 | 4×1,5 | 6xM24 |

| FHG 1750-6-7.8 | 1750 | 92100 | 5,6 | 12,3 | 0,66 | 7,3 | C | 6 | 118 | 280 | 35 | 360 | 440 | 370 | 340 | 400 | 210 | 900 | 930 | 85 | 425 | 388 | 4×2,5 | 6xM24 |

| FHG 2000-6-7.8 | 2000 | 105300 | 5,6 | 12,3 | 0,66 | 7,3 | C | 6 | 118 | 280 | 35 | 360 | 440 | 370 | 340 | 400 | 210 | 960 | 990 | 85 | 425 | 397 | 4×2,5 | 6xM24 |

| FHG 1750-6-8.0 | 1750 | 92100 | 7,5 | 14,25 | 0,68 | 7,6 | D | 8 | 110 | 350 | 35 | 360 | 440 | 470 | 420 | 400 | 210 | 1000 | 1030 | 90 | 430 | 450 | 4×2,5 | 8xM24 |

| FHG 2000-6-8.0 | 2000 | 105300 | 7,5 | 14,25 | 0,68 | 7,6 | D | 8 | 110 | 350 | 35 | 360 | 440 | 470 | 420 | 400 | 210 | 1060 | 1090 | 90 | 430 | 470 | 4×2,5 | 8xM24 |

| FHG 2500-6-8.9 | 2500 | 132500 | 7,5 | 14,25 | 0,68 | 7,6 | D | 8.9 | 110 | 350 | 35 | 420 | 500 | 470 | 440 | 450 | 235 | 1050 | 1080 | 100 | 460 | 500 | 4×2,5 | 8xM30 |

| FHG 3000-6-8.9 | 3000 | 158000 | 7,5 | 14,25 | 0,68 | 7,6 | D | 8.9 | 110 | 350 | 35 | 420 | 500 | 470 | 440 | 450 | 235 | 1050 | 1080 | 100 | 460 | 536 | 4×2,5 | 8xM30 |

| FHG 2500-6-9.0 | 2500 | 132500 | 8 | 18,34 | 0,7 | 9,5 | D | 9 | 110 | 400 | 45 | 420 | 500 | 480 | 470 | 450 | 235 | 1060 | 1090 | 105 | 480 | 540 | 4×2,5 | 8xM24 |

| FHG 3200-6-9.0 | 3200 | 170000 | 8 | 18,34 | 0,7 | 9,5 | D | 9 | 110 | 400 | 45 | 420 | 500 | 480 | 470 | 450 | 235 | 1060 | 1090 | 105 | 480 | 580 | 4×2,5 | 8xM24 |

|

TYPE |

Working- moment [kg cm] |

Centrifugal force [N]

|

Power consumption [kW] |

Nominal current at 400 V [A] |

Power factor [COS ∅] |

Starting current ratio [IA/IN] |

Abbildung Illustration |

Motor base |

Maße Dimensions Cotesmm |

Weight [kg] |

Cable [mm] |

Screw 8.8 |

||||||||||||

| a | b | c | d | d1 | e | f | g | h | k1 | k2 | n | p | ||||||||||||

| FHG95-8-2.2 | 95 | 2850 | 0,3 | 2 | 0,6 | 6,5 | A | 2 | 140 | 170 | 40 | 207 | 255 | 192 | 210 | 225 | 118 | 454 | 478 | 50 | 268 | 50 | 4×1,5 | 4xM16 |

| FHG150-8-2.2 | 150 | 4500 | 0,3 | 2 | 0,6 | 6,5 | A | 2 | 140 | 170 | 40 | 207 | 255 | 192 | 210 | 225 | 118 | 520 | 544 | 50 | 268 | 53 | 4×1,5 | 4xM16 |

| FHG200-8-2.1 | 200 | 6000 | 0,85 | 3,18 | 0,7 | 7 | B | 2 | 140 | 170 | 20 | 207 | 255 | 230 | 220 | 225 | 115 | 594 | 618 | 60 | 274 | 77 | 4×1,5 | 4xM16 |

| FHG340-8-2.3 | 340 | 10210 | 0,85 | 3,18 | 0,7 | 7 | B | 2 | 140 | 170 | 20 | 250 | 300 | 230 | 220 | 272 | 140 | 615 | 640 | 60 | 300 | 98 | 4×1,5 | 4xM16 |

| FHG500-8-3.4 | 500 | 15000 | 1,2 | 3,59 | 0,75 | 4,8 | C | 3 | 83 | 230 | 25 | 280 | 360 | 260 | 280 | 300 | 160 | 600 | 630 | 75 | 330 | 136 | 4×1,5 | 6xM20 |

| FHG680-8-3.4 | 680 | 20420 | 1,2 | 3,59 | 0,75 | 4,8 | C | 3 | 83 | 230 | 25 | 280 | 360 | 260 | 280 | 300 | 160 | 670 | 700 | 75 | 330 | 155 | 4×1,5 | 6xM20 |

| FHG1000-8-4.7 | 1000 | 30000 | 2,7 | 6,71 | 0,6 | 5,5 | C | 4 | 105 | 248 | 28 | 320 | 400 | 300 | 310 | 342 | 180 | 730 | 760 | 80 | 365 | 204 | 4×1,5 | 6xM20 |

| FHG1400-8-7.0 | 1400 | 42000 | 3 | 7,41 | 0,66 | 6 | C | 6 | 118 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 940 | 970 | 90 | 390 | 296 | 4×1,5 | 6xM24 |

| FHG1600-8-7.0 | 1600 | 48000 | 3 | 7,41 | 0,66 | 6 | C | 6 | 118 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 980 | 1010 | 90 | 390 | 310 | 4×1,5 | 6xM24 |

| FHG1750-8-7.8 | 1750 | 52500 | 4 | 9,87 | 0,68 | 6,4 | C | 6 | 118 | 280 | 35 | 360 | 440 | 370 | 340 | 400 | 210 | 900 | 930 | 85 | 425 | 388 | 4×2,5 | 6xM24 |

| FHG2000-8-7.8 | 2000 | 60000 | 4 | 9,87 | 0,68 | 6,4 | C | 6 | 118 | 280 | 35 | 360 | 440 | 370 | 340 | 400 | 210 | 960 | 990 | 85 | 425 | 397 | 4×2,5 | 6xM24 |

| FHG2500-8-8.9 | 2500 | 75000 | 4,5 | 10,83 | 0,7 | 6,1 | D | 8.9 | 110 | 350 | 35 | 420 | 500 | 470 | 440 | 450 | 235 | 1050 | 1080 | 100 | 460 | 500 | 4×2,5 | 8xM30 |

| FHG3000-8-8.9 | 3000 | 90100 | 4,5 | 10,83 | 0,7 | 6,1 | D | 8.9 | 110 | 350 | 35 | 420 | 500 | 470 | 440 | 450 | 235 | 1050 | 1080 | 100 | 460 | 536 | 4×2,5 | 8xM30 |

| FHG2500-8-9.0 | 2500 | 75000 | 7 | 18,15 | 0,56 | 7,3 | D | 9 | 110 | 400 | 45 | 420 | 500 | 480 | 470 | 450 | 235 | 1060 | 1090 | 105 | 480 | 540 | 4×2,5 | 8xM24 |

| FHG3200-8-9.0 | 3200 | 96000 | 7 | 18,15 | 0,56 | 7,3 | D | 9 | 110 | 400 | 45 | 420 | 500 | 480 | 470 | 450 | 235 | 1060 | 1090 | 105 | 480 | 580 | 4×2,5 | 8xM24 |

| FHG4000-8-9.0 | 4000 | 120000 | 7 | 18,15 | 0,56 | 7,3 | D | 9 | 110 | 400 | 45 | 420 | 500 | 480 | 470 | 450 | 235 | 1160 | 1190 | 105 | 480 | 600 | 4×2,5 | 8xM24 |

|

TYPE |

Working- moment [kg cm] |

Centrifugal force [N]

|

Power consumption [kW] |

Nominal current at 400 V [A] |

Power factor [COS ∅] |

Starting current ratio [IA/IN] |

Abbildung Illustration |

Motor base |

Maße Dimensions Cotesmm |

Weight [kg] |

Cable [mm] |

Screw 8.8 |

||||||||||||

| a | b | c | d | d1 | e | f | g | h | k1 | k2 | n | p | ||||||||||||

| FHG 680-10-3.4 | 680 | 12550 | 0,95 | 2,57 | 0,58 | 2,7 | C | 3 | 83 | 230 | 25 | 280 | 360 | 260 | 280 | 300 | 160 | 670 | 700 | 75 | 330 | 155 | 4×1,5 | 6xM20 |

| FHG 1750-10-7.0 | 1750 | 30100 | 5 | 8,76 | 0,69 | 5,3 | C | 6 | 118 | 280 | 35 | 320 | 400 | 370 | 340 | 340 | 185 | 980 | 1010 | 90 | 390 | 310 | 4×1,5 | 6xM24 |

| FHG 2000-10-7.8 | 2000 | 34400 | 5 | 8,76 | 0,69 | 5,3 | C | 6 | 118 | 280 | 35 | 360 | 440 | 370 | 340 | 400 | 210 | 960 | 990 | 85 | 425 | 397 | 4×2,5 | 6xM24 |

General specifications

Zasilanie:

Power Supply:

Voltages from 115 V to 690 V at 50 Hz and 60 Hz available

Degree of protection:

IP 66

Thermal class:

F (155 °C) according to DIN EN 60034-1

Tropical insulation:

Standard

Electrical connection:

Use high flexible cable for heavy mechanical stress. Example: H07RN-F or A07RN-F according to DIN VDE 0282.

Permissible ambient temperature:

-20 °C to + 40 °C.

Special versions with cold steel to -65 °C also available on request.

Operating mode:

Continuous operation (S1) and discontinuous operation at 100 % centrifugal force.

Hoods:

Hoods made from pressed sheet metal or stainless steel, comprise the special shape. A silicone seal provides optimum protection against the ingress of dust and water.

Assembly:

Without limitation, motors can be mounted in any position.

Color coating:

Standard RAL 6011. Other colors available on request.

Type code:

The type code is read as follows:

- First block number = Working Moment in kgcm,

(working moment = 2 x static moment) - This is followed by a hyphen and then the pole number,

- Where: 4 = 1460 rpm 6 = 980 rpm (at 50Hz mains frequency),

- Behind the second dash, the size is specified.

Special designs and accessories available on request:

- Anti-condensation heating,

- Thermistor,

- Special steel bearing retainer (see special catalog),

- Waterproof terminal box with a special sealant shed Connection cables with different Cable specifications in different lengths available.